Lanyards consisting of a single length of webbing often restrict the user’s range of movement to a 6′ (1.8 m) radius around the anchor location. Another issue is 100% protection. To move, the lanyard must be disconnected, possibly creating fall hazard exposure. To address these issues, a Y-lanyard may be used.

Y-lanyards typically consist of a harness connecting snaphook at the center with two lanyard “legs,” branching off from an energy absorber to form a “Y” or “V” shape. Several different models, lengths, and configurations are available, but they all serve the same purpose—to allow greater protected mobility and maintain 100% connection. Because of their shape, Y-lanyards go by many slang names such as lobster claws, Y or V lanyards, doubles, and twin legged lanyards. Regardless of the name, the function is the same: one lanyard with two connecting legs.

A user of a Y-lanyard first connects one leg to an anchor point and then moves toward a work location. The second leg can then be connected to a new anchor and the original leg removed. The key to safe use of these lanyards is not disconnecting the first leg before the second leg is anchored. This allows complete fall protection for users on the move. Such lanyards do have some associated hazards, especially when used to climb vertical structures.

When using a Y-lanyard, a worker naturally wants to use the maximum length of one leg before connecting the second leg. By so doing, the worker reduces the number of connections and disconnections, as well as the amount of energy expended. Consequently, the worker often climbs higher than the first anchor point to connect the second leg. If a 6′ (1.8 m) lanyard is being used, this will expose the worker to free falls in excess of 6′ (1.8 m).

General practice dictates that a workers should not over-climb an anchorage. This can be difficult because if workers do not over-climb anchorages, the increase in vertical height climbed is only equal to the height workers can reach above their heads, typically only a couple feet. When climbers are observed using these lanyards, they often put themselves in a position where falls in excess of 6′ (1.8 m) can occur. The lesson is that these lanyards are great for traversing, but are not the best tool for vertical climbing.

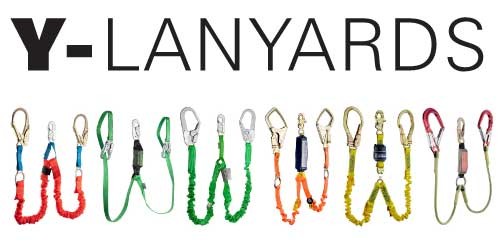

Y-Lanyard Types

Not a complete list of all available lanyards, This is a sampling to illustrate variety.

1 Lanyard Connector

The natural tendency is to select a lanyard with the largest connector, but this is not always the best choice due to compatibility issues. Identify the areas of use and select the best connector. Ideally, connectors with 3,600 lb. gates meeting ANSI Z359.12 should be used.

2 Harness Connector

This connector attaches to the full body harness. This connector (snaphook or carabiner) is usually smaller (3/4″ gate) since it commonly attaches to a standard harness D-ring. Although exceptions exist, the majority of applications call for this connector to attach to the dorsal D-ring on the harness.

3 Energy Absorber

The energy absorber is located at the central lanyard connection on Y-lanyards. For single leg lanyards, the energy absorber will be located on one end, typically attached to the harness. Depending on the style and manufacturing method, hip-loading or a dual connection issue may be encountered.

4 Lanyard Material

The leg of the lanyard can be made from webbing, tubular webbing, cable, rope or specialty material (Kevlar, coated webbing, etc.). The material must be synthetic or cable and have a minimum breaking strength of 5,000 pounds.

5 Lanyard Legs

Lanyards typically come in single or double leg styles. Lanyards with two legs are the most common, since they allow a person to move from one location to another and remain connected by alternating the connection of the lanyard legs. The most common lanyard length is 6′ (1.8 m) although other lengths are available.

6 Label

A label is present on all lanyards made under the ANSI standard. The label is important as it provides a model, manufacturer, warnings, material of construction, and usually a serial number. If the label is missing or unintelligible, the lanyard cannot be identified or traced back to a source, usually forcing the lanyard to be removed from service.

Modular

Energy absorber with interchangeable connector. Pictured is a 6′ (1.8m) Y-lanyard attachment with large snaphooks on the connecting ends. Several lanyard options can be attached to this energy absorber.

Rope Lanyard

Y-lanyard with two large aluminum snaphooks on the connecting ends and a small steel snaphook in the middle. This lanyard uses rope as the lanyard material and a forged connecting ring to attach all three components together.

Large Hook

Y-lanyard with a 12 ft FF energy absorber. Very large snaphook on the connecting ends and small snaphook for harness connection. This lanyard has D-rings along the length of the lanyard to facilitate rescue. The rescue system can be attached to the D-ring, enabling the rescuer to lift the rescue subject and disconnect the connected snaphook.

Tubular Webbing

Y-lanyard with POY type energy absorber in each leg. This lanyard has two large snaphooks on the connecting ends and one small snaphook in the center. This type of lanyard (Y-lanyard with large connecting hooks) is the most common type of lanyard in use.

Rescue

Y-lanyard that uses POY energy absorber, large snaphooks on the connecting end and a small snaphook in the center. This lanyard also incorporates rescue D-rings in the connecting end and webbing loop (can be used for rescue connection) connecting the components together.

Tie-Back

Y-lanyard with a 6 ft FF energy absorber and tie-back option. This lanyard is designed to wrap around structure and connect back into the lanyard’s webbing. The gates of the snaphooks are designed for this connection. Users must be cautious to close the gates completely and align the hook properly.