Your cart is currently empty!

Energy Absorbers

Energy Absorbers

Energy absorbers are a critical component to any fall protection system. In the event of a fall an energy absorber reduces the energy exerted on the user in order to keep impact forces around 900 lb.—well below the injury threshold for the majority of the population.

A fall protection system without an energy absorber exposes its users to risk of injury. Simple lanyards made of rope, webbing, or cable will not absorb enough energy to keep impact forces below acceptable levels. Whenever an energy absorber is used in a fall, it must be immediately removed from service and never used again. Under no circumstances should a previously deployed energy absorber be used again even if it has deployed only a little bit.

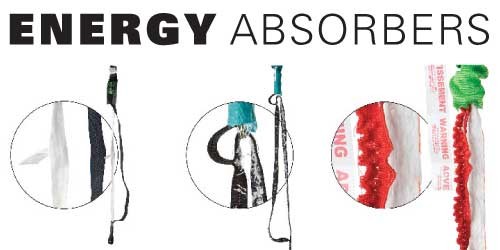

There are several methods used in the construction of energy absorbers. Here is a quick overview of the common types of energy absorbers and how they lower the impact forces, reducing injuries:

Loomed Material

Loomed energy absorbers function somewhat like strips of Velcro™. Two strips of nylon material are woven together and sewn into the lanyard. Under load, the two nylon strips peel apart, similar to Velcro™. The worker’s weight and fall distance determine how much material becomes torn. If a fall generates enough energy to tear through the entire length of material, a strap prevents the system from separating altogether.

Stitched Webbing

Stitched energy absorbers work in a similar manner to loomed material. Two parallel strips of webbing are stitched together along a common edge so they will peel apart under load. Manufacturers are able to vary the amount of stitching to create different strengths of material. Many varieties of stitched energy absorbers are available. Some include metal O-rings that can be used to rip open the stitches, some use extra-wide webbing, and some use varying stitch patterns. All of these designs use breaking stitches to dissipate fall energy.

Partially Oriented Yarn (POY)

This type of energy absorber relies on webbing elasticity to absorb fall energy. A flat length of webbing is manufactured so that it stretches under load, thus providing a deceleration distance. The concept is similar to a rubber band that will only stretch once. The webbing is manufactured using very loose weaves between strands. This gives the lanyard a soft and flexible feel. Under load, the strands become taut and stretch. These energy absorbers always have a protective sleeve of tubular webbing surrounding the lanyard connector.

Articulated Mannequin Drop Tests

To show just how effectively energy absorbers lower impact force, we put Manny, our articulated mannequin, to the test with a variety of lanyards, harnesses, and connections.

The red line traces the force on Manny (who weighs 200 lb.) as he bottoms out from his 6′ fall.

1. THREE-STRAND NYLON ROPE LANYARD

Maximum Arrest Force: 2,114 lb.

You can see why lanyards without energy absorbers are not used in fall protection.

2. Y-LANYARD – HIP CONNECTION

Maximum Arrest Force: 1,815 lb.

Connecting a leg of your Y-lanyard to your hip can lead to a situation known as hip-loading, where the stored lanyard on the hip prevents the active lanyard leg from completely deploying, which increases the fall arrest forces and side-loads the body.

3. WAIST BELT BELT WITH ROPE LANYARD

Maximum Arrest Force: 2,504 lb.

Waist belts are illegal for fall protection for a reason—they can cause significant injury, even if used with an energy absorber.

4. ENERGY ABSORBING LANYARD

Maximum Arrest Force: 711 lb.

When properly used, energy absorbing lanyards limit arrest forces to below injury levels.