Inspecting: Corrosion | Paint | Chemical Exposure/Contact

EQUIPMENT INSPECTION

What to Look for!

Part 2 of 3

FUNCTIONAL CARABINER

The zinc coating has worn off on the bottom half of carabiner.

SURFACE CORROSION

No signs of pitting, this carabiner is still usable providing the gate is fully operational.

EXTENSIVE CORROSION

Signs of pitting of the metal, preventing the gate from operating properly. This carabiner should be retired from use.

Paint

Fall protection equipment is often present during painting. Overspray, cleaning agents, and saturation by paint is not uncommon damage to this equipment. Some additional research is required to determine the type of paint and if there are any additives or ingredients that will adversely affect the equipment. Paint will usually affect the equipment in one of three ways: the function on gates of connectors, saturating the webbing, thus becoming brittle once dry, and/or by chemical damage by additives, hardeners or other paint qualities. Minor overspray by a water-based paint is not usually considered enough to retire the item providing the function and condition is not affected and the webbing is still supple. A section of webbing that is saturated and hardened would be cause for retirement.

MINOR OVERSPRAY

Overspray is common and not usually an issue, providing the chemical properties of the paint does not affect the harness and the overspray does not hinder connectors or adjustments.

HEAVY SATURATION

Saturation of webbing by paint, which hardens the webbing, limiting ability to stretch during fall arrest.

FUNCTION

Paint is an issue when it gets so heavy that it hinders gates from opening or working properly.

BEST PRACTICE

Economy harnesses can be used and discarded after the job, or harnesses with protective coatings can be used.

Ultraviolet Light (UV) Damage

Ultraviolet light begins to bleach and dry synthetic materials out. Eventually the material becomes brittle and loses it’s strength and elastic properties. It is important that any synthetic be removed from service before this occurs. Like other inspection issues, UV is difficult to quantify because the duration and intensity of the light varies from one location to the next.

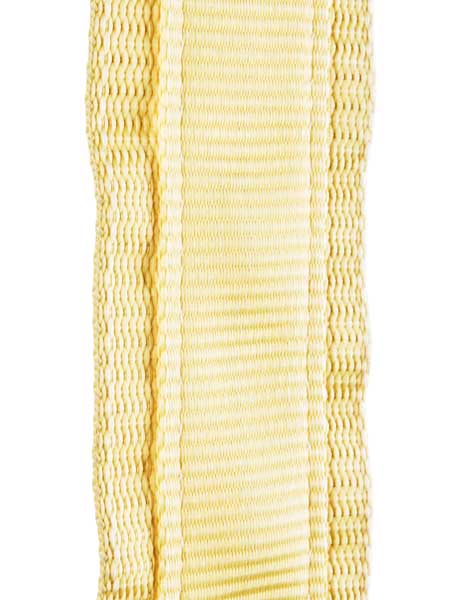

NEW WEBBING

No UV exposure.

UV EXPOSED

Discoloration caused by exposure to the sun. Material becomes faded, dry and loses its strength and elasticity. Remove from service.

Chemical Exposure/Contact

Chemical exposure is a challenging inspection item since there are thousands of different chemicals and active ingredients. Most equipment manufacturers can provide specific insight with chemical exposure, but specific published guidelines are rarely available. Research is required to find what chemicals are in use and how they will affect nylon, polyester, steel, and aluminum components. Sulfuric acid (automotive batteries) deserves specific mention since it is very damaging to synthetics. It readily dissolves the material and extreme care needs to be taken using fall protection equipment around sulfuric acid. Gravitec recommends the inspector understands the work process where equipment is being used, refers to the MSDS of the chemical involved, and contact the item’s manufacturer for direction.

Need Help Inspecting Your Equipment

If you have any additional questions or need a replacement, contact our Equipment Advisors at 800.755.8455.